Mastering the Art of

Precision Printing

As a seasoned professional in the printing industry, I specialize in utilizing advanced technologies to create stunning visuals on a variety of materials. My expertise extends to operating vinyl and Direct to Substrate (DTS) printers, allowing me to bring designs to life with precision and attention to detail.

DTS Printer

Print on 1/4in Foam Core with Matte Laminate

Vinyl Printer

Printer Technologies:

I leverage both vinyl and Direct to Substrate printers to achieve optimal results. A significant aspect of my role involves meticulous file setup to ensure flawless printing.

This includes adding sufficient bleed to accommodate various surfaces and allowing room for potential errors. I also excel in extending images to create seamless patterns, adjusting image quality for optimal print output, and meticulously color matching specific hues.

Matte Vinyl with Matte Laminate on Frosted 1/8in Acrylic

Lamination Expertise:

Understanding the importance of durability, I incorporate lamination into my process based on the intended use of the printed material. This step not only enhances protection but also ensures resilience against the elements and the wear and tear expected at trade shows, events, and beyond.

In every step of the printing process, my commitment to quality, precision, and adaptability shines through. From file preparation to material handling and finishing touches, I bring a comprehensive skill set to the art of printing, ensuring that each project meets and exceeds expectations.

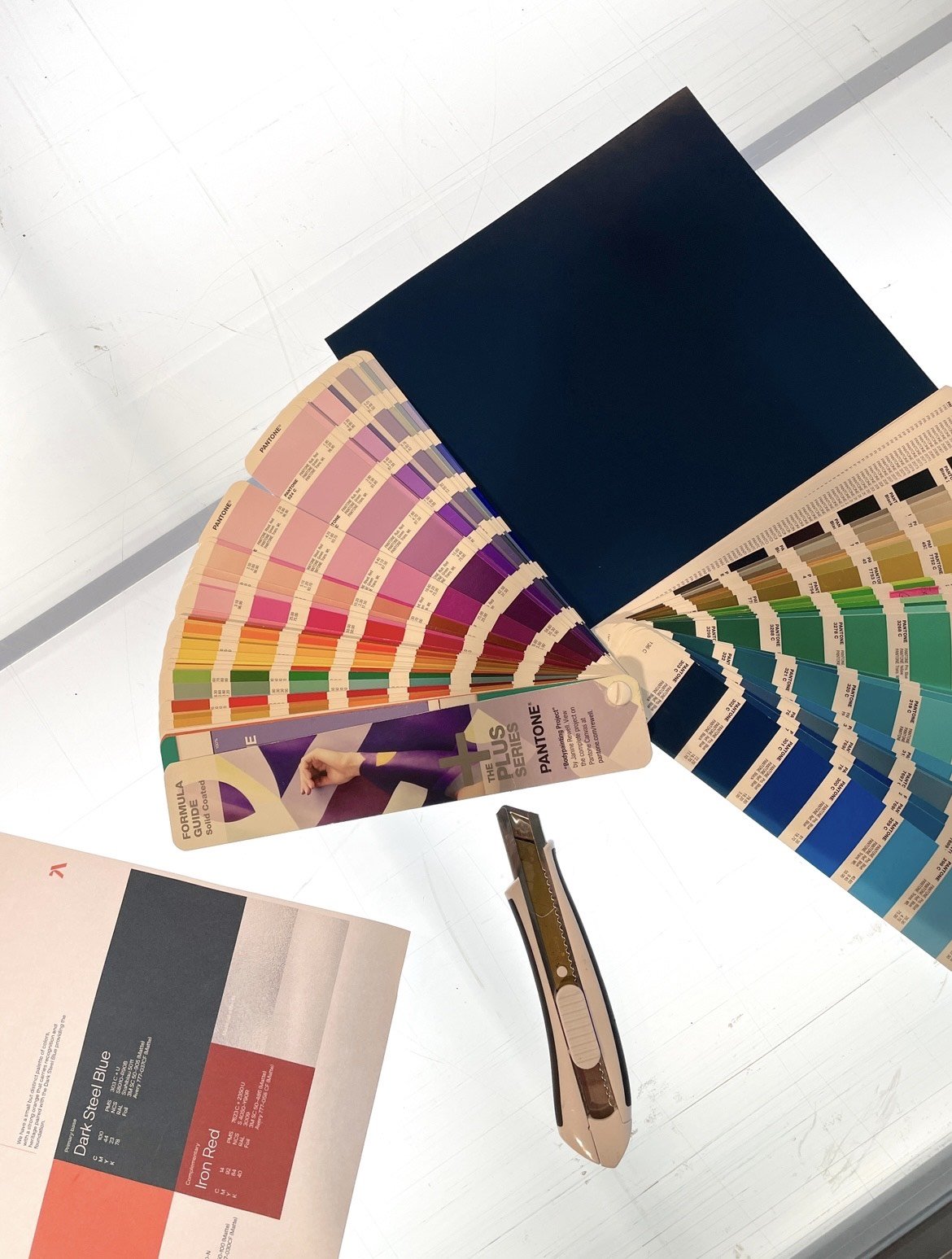

Color Matching on the Laminate Table

Material Mastery:

My proficiency extends across a diverse range of materials, each requiring specialized handling. From the elegance of acrylic and canvas to the durability of banner stand material, wood, translucent vinyl, PVC, metal, and more – I have successfully printed on materials of varying thicknesses.

I am well-versed in the unique sensitivities of each material, ensuring that the printing process prevents any damage to the final product. This involves adjusting heat settings for proper drying and meticulously monitoring the printing process.

Precision Cutting:

Employing techniques tailored to each material type. Whether it's adjusting pressure settings for the cutter or determining the optimal cutting speed, I ensure that the final product meets the highest standards.

I differentiate between a swift dye cut, ideal for fast cuts, and a slower cut, which is carefully selected based on how the graphic will be used.